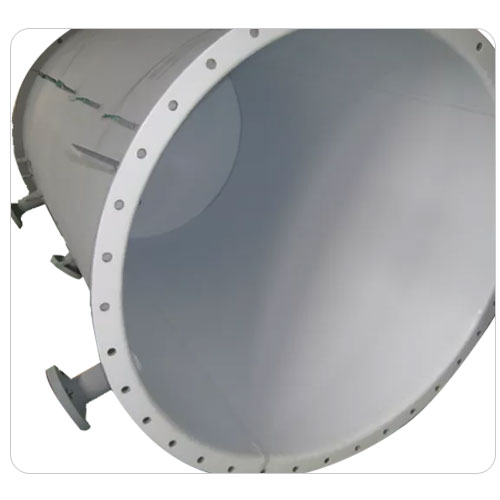

PVDF/ECTFE/FEP/PFA/PTFE SHEET LINING ON METAL EQUIPMENT

Fluoropolymer sheet lining is designed to withstand the corrosion of virtually all corrosive fluids. It possesses an outstanding combination of chemical, thermal and non-stick properties, coupled with mechanical durability

There are two types of sheet lining available:

(1)Bonded Sheet Lining

Fluoropolymer sheet with glass fiber backed is bonded to metal with help of adhesive & Joints are subsequently thermo welded together. This system is available in 1.5,2, 3 & 4 mm thick sheet of PVDF, ECTFE FEP,PFA & PTFE

This is suitable upto max 120°C & is suitable for Full Vacuum.

(2)Loose Sheet Lining

Fluoropolymer sheet is welded together & inserted into metal equipment without bonding .This system is available in 1.5,2, 3 & 4mm Thick sheet of FEP, PFA & PTFE .This is suitable Upto 200°c but not suitable for vacuum Application.

Corrosion Resistance of Fluoropolymer

A. PVDF

Resistant to most acids, alkalis, aliphatic and aromatic hydrocarbon, alcohols and strong oxidizing agent. Highly polar solvents such as acetone & acetate may cause swelling

-

B. ECTFE(HALAR)

Resistant to strong acids, organic solvent .chlorine and aqueous caustic. Not stress cracked any organic fluids. Swelled by some chlorinated solvents.

-

C. FEP, PFA, PTFE

Inert to virtually all chemicals with the exception of a few per fluorinated compounds

Applications of Sheet Lining

- Agitators Sheet Lining

- Reactors Sheet Lining

- Columns internals Sheet Lining

- Storages Tanks Sheet Lining

- Spare for Glass lined Reactors

- Centrifuges Sheet Lining

- Road Tankers Sheet Lining

- Containers Sheet Lining

- Vessels Sheet Lining

- Hoods Sheet Lining

- Columns Sheet Lining

- Chimneys Sheet Lining

- Ductings Sheet Lining

Industries We Serve

- Pharmaceuticals API & Bulk Drugs

- Chemicals Processing

- Agro Chemicals

- Bio – Chemicals

- Plating

- Food Industry

- Semi Conductor

- Aerospace

These Sheet linings are available in PVDF, ECTFE – HALAR, FEP, PFA, PTFE etc as per IS 4682 (Part 4) Code

Our Technical Director Mr. Bharat P Kapadia has participated in 1 week training at Lenzburg /Switzerland at Symalit Ltd. The practical Training done in industrial conditions included welding of Fluoropolymer, thermoforming of sheet, welding equipment & testing of welding for lining on steel equipment.